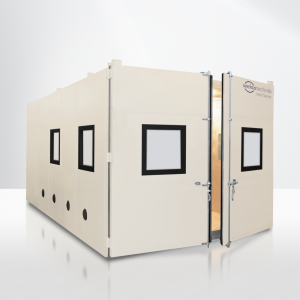

Specifications

- Temperature range expandable to -40 °C and to +80 °C

- Shock and scratch-resistant interior surfaces thanks to glass-fiber reinforced plastic (GRP)

- Saddle roof with an inclination of at least 30°

- Corrosion-resistant indirect temperature controls

- Psychrometric measuring system for temperature and humidity control

- Heating elements to control test chamber temperature, with overtemperature protection

- Ventilation device to flush the test chamber with fresh air