Specifications

- Possibility to use of metal parts, such as conventional metal tools and feed systems, in the microwave field

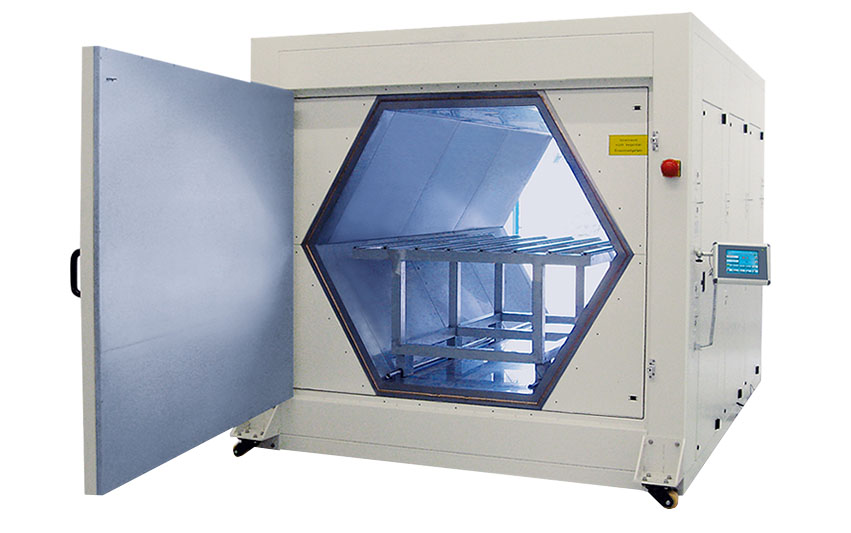

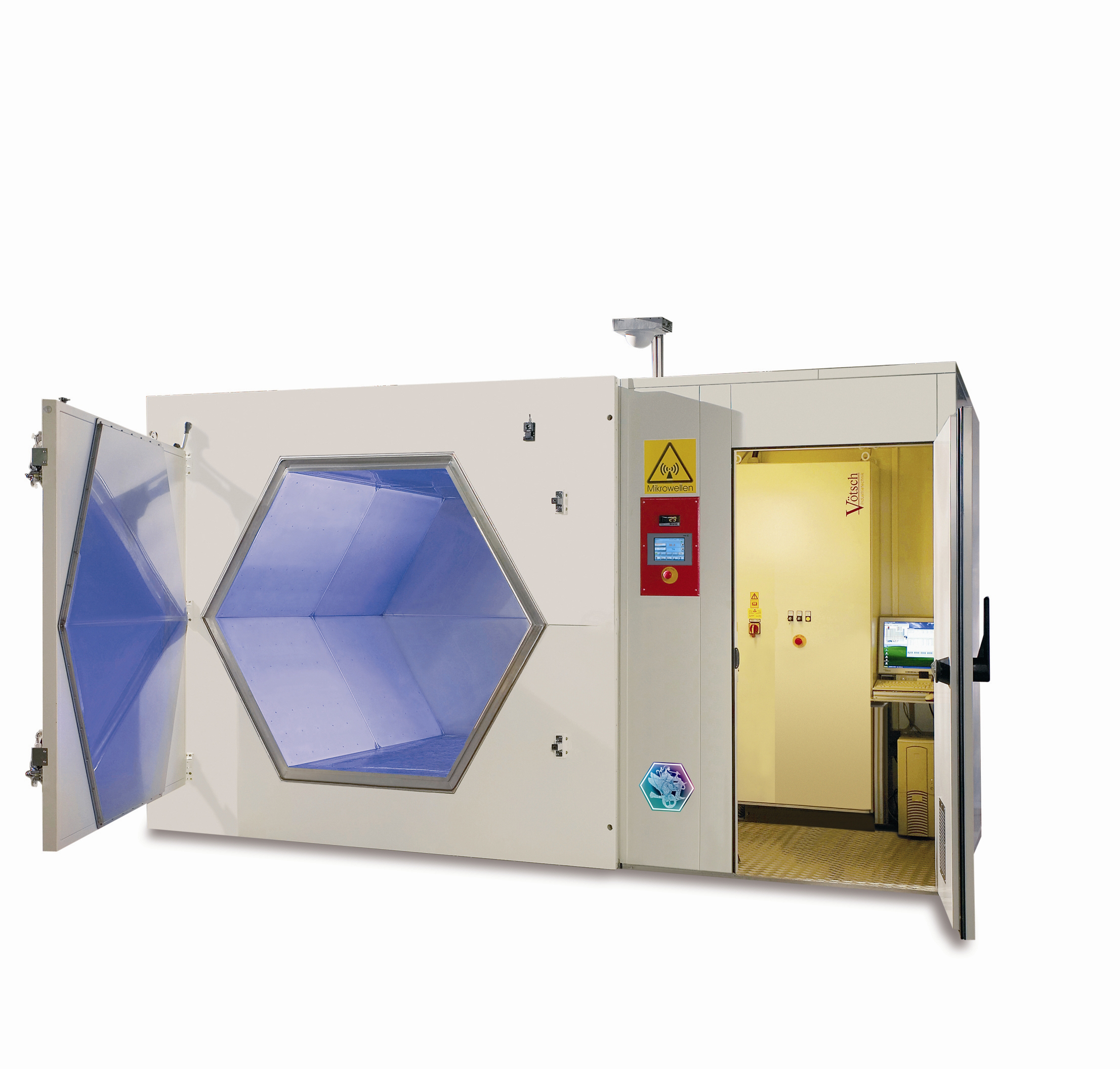

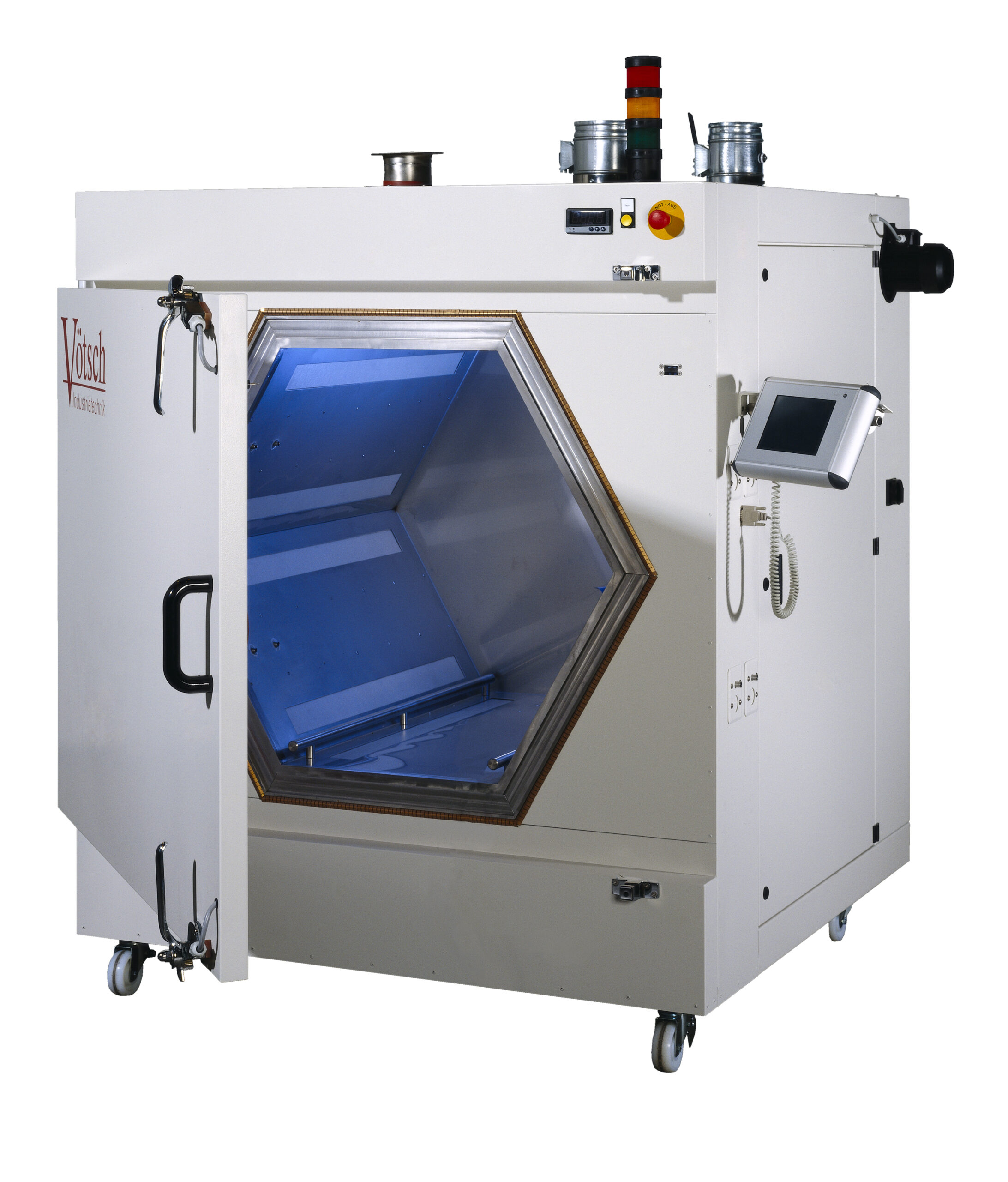

- High degree of product quality thanks to the maximum homogeneity of the microwave fields: Hexagonal chamber structure. By using microwave absorbing tool materials, additional positive effects can be achieved.

- Sizes from laboratory scale to large systems, e.g., as are required in the aerospace industry, can be achieved

- The modular design allows a flexible adjustment to your product

- Precise heating of the products

- Hybrid heat transfer possible