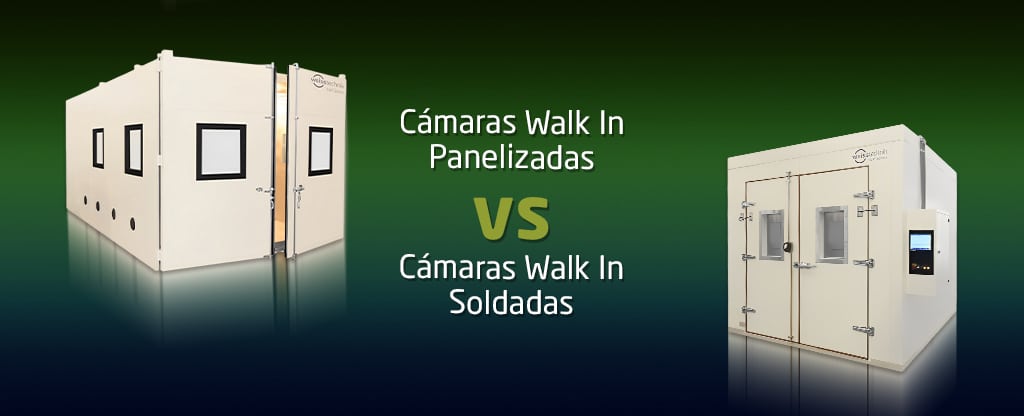

In the environmental testing industry, having the right testing equipment is key to ensuring the reliability and performance of products. One of the most essential tools is walk-in chambers, used for large-scale testing in various industries, from automotive to electronics and telecommunications. In this article, we’ll explore the differences between two types of walk-in chambers: paneled and welded chambers. This detailed analysis will help you make an informed decision on which is the best option for your specific testing needs.

What is a Walk-In Chamber?

Before diving into the details of the types of walk-in chambers, it’s important to define a walk-in chamber. Walk-in chambers are large, enclosed spaces designed for environmental testing, where products, components, or entire systems are subjected to specific temperature, humidity, and pressure conditions, replicating extreme environments to evaluate their reliability and durability.

Common Applications of Walk-In Chambers:

- Testing product resistance to extreme temperatures

- Evaluating electronic equipment under high humidity

- Simulating harsh environmental conditions for automotive products

- Stress testing of vehicles and industrial components

Paneled Walk-In Chambers

Paneled walk-in chambers are constructed from modular foam panels that are assembled on-site where they will be used. This feature gives them great versatility, as they can be configured and adapted based on the available space dimensions. Paneled chambers offer an excellent option when flexibility in design, space limitations are required.

Panelized Walk-In Chamber Features:

- Design Flexibility: Paneled chambers adapt to various space configurations. This flexibility is essential in environments where dimensions or access are limited, as the modular panels allow for installation in spaces with physical restrictions.

- Ease of Transport and Assembly: Since paneled chambers are assembled on-site, the panels can be transported in pieces, making mobility and transportation easier. This is especially useful for temporary installations or in areas where access is difficult.

- Large-Scale Testing: Paneled chambers allow for large-scale testing, such as the analysis of entire vehicles, industrial equipment, or large batches of products. Their ability to accommodate large objects makes them an ideal solution for the automotive and manufacturing industries.

- Ideal for mild temperature applications and test requirements up to +85°C.

- More cost effective and ideal for the majority of common test standards.

Welded Walk-In Chambers

Welded walk-in chambers are solid structures made of stainless steel, designed to withstand more extreme environmental tests. These chambers offer greater durability and robustness compared to paneled ones, making them ideal for demanding testing environments and extreme temperature and humidity conditions.

Welded Walk-In Features:

- Exceptional Durability: Welded chambers are built with high-strength materials like stainless steel and welded seams ensuring a strong and durable structure. This sturdiness is essential for long-term testing or when products are subjected to extreme environmental conditions.

- Resistance to Harsh Conditions: One of the main advantages of welded chambers is their ability to withstand extreme conditions. Thanks to their fully sealed structure, they can perform tests under very high or low temperatures and humidity levels without the risk of leaks or deterioration. They are also ideal for testing procedures that require fast temperature transition rates.

- Available in Various Configurations: Welded chambers can be designed in one or several pieces, facilitating easy installation based on the client’s specific facility requirements.

Which Option is Best for You?

The choice between a paneled or welded walk-in chamber will depend on several key factors, such as the type of tests you want to perform, the dimensions of the products to be tested, the location of your facility, and your budget.

- If flexibility is your priority and you have a space with physical restrictions, the paneled chamber may be the best option.

- If you need to perform tests under extreme environmental conditions such as high temperature and humidity conditions and are looking for a long-term durable solution, the welded chamber is an excellent alternative.

Both options can be equipped with advanced cooling systems such as Weiss Technik’s LEEF technology, which optimizes energy consumption and ensures efficient and sustainable performance over time.

Conclusion

At Weiss Technik, we have over 40 years of experience in manufacturing customized test chambers, both paneled and welded. Whatever your choice, we will provide the right solution for your testing needs, with the quality and reliability that define our products.